Lithium battery price and the factors affecting prices of lithium battery

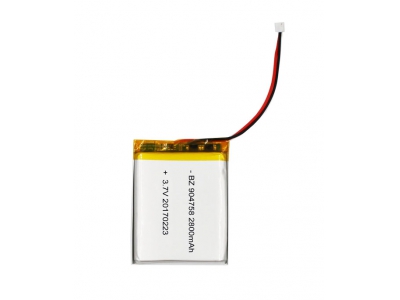

Lithium battery price compositionThe price of lithium battery is mainly composed of three major components: battery cell, protection board and outer casing. At the same time, due to the power consumption and current of the electric appliance, the material of the connecting piece between the batteries (conventional nickel sheet, formed nickel piece) The selection of copper-nickel composite sheets, jumpers, etc. will affect the cost. Different connectors may also have a greater impact on cost, and different PACK processes will also affect the cost.

Factors affecting the price of lithium batteries

First, the selection of cells:

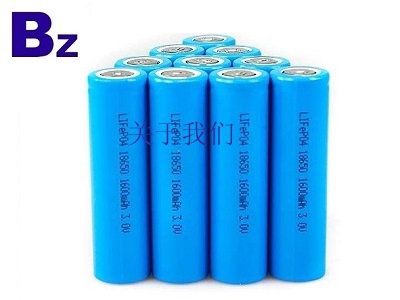

1), the selection of cells for different material will affect the price of the entire lithium battery. Lithium batteries according to different cathode materials, there will be lithium manganate (3.6V), lithium cobalt oxide (3.7V / 3.8V), lithium nickel cobalt manganese oxide (commonly known as ternary, 3.6V), lithium iron phosphate (3.2V), lithium titanate (2.3V/2.4V), The battery cell of various material systems , the voltage platform, safety factor, cycle number, energy density ratio, working temperature, etc. are different.

2), the price of batteries of different brands will also vary greatly. The quality (safety, consistency, stability) of each brand of batteries produced by the market to survive the inferior is basically proportional to the price.

Second, the demand and design of lithium battery PCM

PCM design can be divided into: basic protection, communication, BMS

Basic protection: basic protection includes overcharge, over discharge, overcurrent and short circuit protection, and can increase over temperature protection according to product requirements.

Communication: The communication protocol can be divided into I2C, RS485, RS232, CANBUS, HDQ, SMBUS, etc., as well as a simple power display, which can be indicated by an LED.

BMS: BMS is the first letter combination of BATTERY MANAGEMENT SYSTEM, which is called battery management system. It is called battery nanny or battery butler. It is mainly to intelligently manage and maintain each battery unit to prevent overcharging and overdischarging of the battery. Extend battery life and monitor battery status. Its main functions include: real-time monitoring of battery physical parameters; battery state estimation; online diagnosis and early warning; charging, discharging and pre-charging control; balance management and thermal management. The secondary system is mostly used in electric vehicle batteries.

Third, the needs and design of lithium battery casing

Lithium battery case design can be divided into: PVC heat seal, plastic, metal

PVC heat sealing: What kind of outer casing packaging form is used outside the battery pack, mainly depends on the specific needs of the customer‘s product. For the PVC heat sealing package type, it is generally applicable to the battery cells string and the quantity is small, and the overall weight is light. In the case of (≤ 2kg), it can be used. However, for a battery pack with an overall weight of ≥1kg, it is necessary to add a fixing bracket between the batteries, and after the outer glass fiber board is protected, the PVC is heat-sealed.

Plastic: plastic shell, mainly after different battery packs are shaped, the shell involved may need to open the mold, the mold cost is not a small expense, such as the pre-development period, the product is not stereotyped, you can use the hand shell proofing (hand board The strength is not as good as the material strength after opening the mold.) The requirements for the material and process of the outer casing (especially with the three-proof requirements) will also affect the cost.

Metal: The metal casing is also the same as the plastic casing. Before the product is not finalized or the quantity is not much demand, it is recommended to use the sheet metal sample. This is mainly because the sample preparation has a short delivery time, such as a large batch size, it is also recommended to open the mold. For metal casings with waterproof rating requirements, it will also greatly affect the cost, as well as the metal casing required for special materials (such as titanium alloy), the cost will be higher.

The cost of a lithium battery is mainly composed of a battery cell, a PCM, and a structural member, and a PACK fee, an aging fee, and a management fee of the company are also required. At the same time, due to the technical difficulty of the product, the purchase amount, the non-performing rate requirements are different, the price of lithium batteries will vary greatly!